Applications using Dimensional Measurement Products

Dimensional Measurement of Gear Shafts, Sprocket Wheels, Bevel Gears

Dimensional Measurement of Gear Shafts, Sprocket Wheels, Bevel Gears

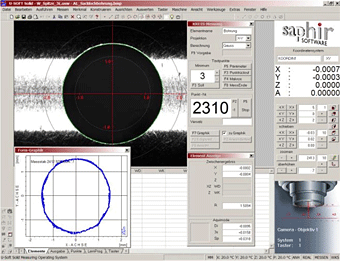

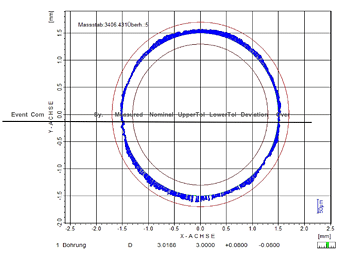

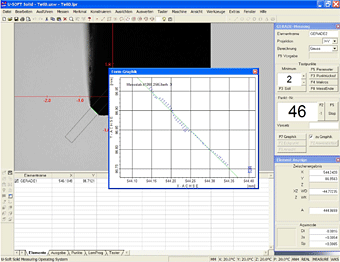

Traditionally it is difficult to measure complex features such as undercuts, oil holes or feather key grooves in a single measurement sequence. The Schneider Shaft measuring machine WMM is available as a multi-sensor machine to measure all the required features on a single machine. In addition to the classical features which can be measured by camera, 3D features can also be measured with the addition of tactile probes. Diascopic light sources allow dimensional measurement of features on external contours such as chamfers, whereas the episcopic light allows detailed analysis of blind features such as oil holes.

Features which can be measured include: length, diameter, groove, radius, angle, chamfer, axial and radial runouts, concentricity, undercuts, oil holes on the lateral area, flatness, cylindrical and conical shapes.