Applications using Dimensional Measurement Products

Dynamic Dimensional Measurement of Cutting Tools

Dynamic cutting tool blade measurement

The Schneider range of WMM shaft measuring machines analyse lengths, diameters, radii, angles, chamfers, as well as geometric and dimensional tolerances – with unparallelled speed, accuracy and repeatability.

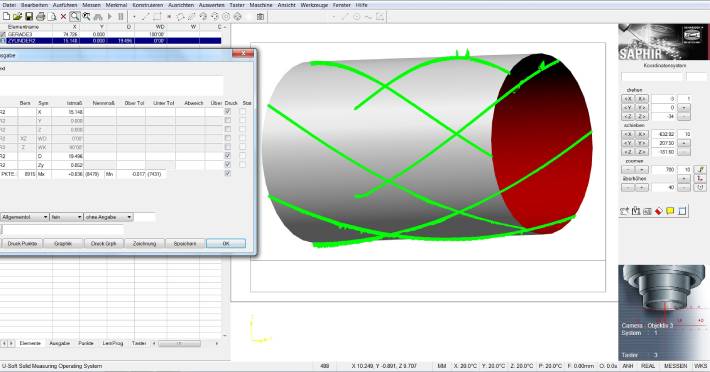

The latest version of Saphir software now allows dedicated, dynamic measurement of cutting tool blades (flute tooth), giving a fast and dynamic record of individual blades with a high point density.

DXF files of the cutting tool are imported into the Saphir software for full evaluation in 2D and 3D. The system can measure individual blades or all blades simultaneously as a ‘minimum circumscribed circle (edge)’.

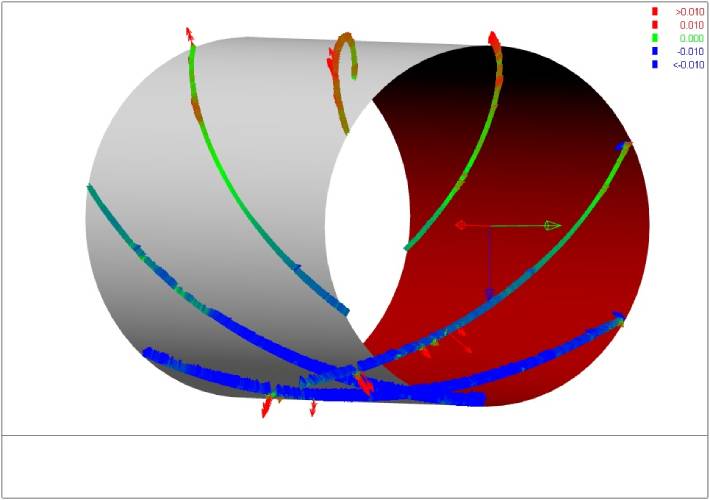

3D turbine impeller with tolerance colour

The causes of tool faults can thus be determined and documented accurately. Measurement results are automatically adjusted or calculated based on the selected reference (blade, tool shank, tool holder) and are output as detailed tables or graphs.

The software also includes a patented, dynamic wobble compensation, whereby the evaluation is adjusted according to the reference used (for example, blade to tool shank or blade to tool holder).

The camera captures approx. 60 images/sec, recording the measurement points during rotation and assigning them to the relevant blade. Measurement speeds of 1 seconds per revolution on a diameter of 20mm are easily achieved.

3D results cutting tool

This configuration is suitable with WMM450 or WMM600-1200 models of shaft measuring machine.

.