News: Press Release

6th March 2018

More News

4D Technology event at Rolls-Royce Technology Hub, Derby University

Seminar: 3D micro-surface measurements of precision components, Wednesday 8th November 2023, 8.30am - 12.15pm

12th October 2023 • Read »

4D Technology event at Glyndwr University, 16 March 2023

4D Technology in conjunction with Quantum Design are hosting a workshop ‘Inteferometry for Metrology’ at the OpTIC Technology Centre, Glyndwr University, St Asaph on 16 March 2023.

23rd January 2023 • Read »

Alignment and Level in the Nuclear Industry

Taylor Hobson measurement products have been used for many years in the nuclear industry for checking, measuring and monitoring alignment and level. Camera systems and motorised focus accessories allow the telescope to be operated remotely from the telescope.

13th September 2022 • Read »

A fresh approach to dimensional metrology from the comfort of your desk

An easy way to view the full dimensional metrology range in one virtual showroom:

8th July 2021 • Read »

peen marking / engraving - micro features

Peen marking/engraving for parts identification is a critical element in industries such as aviation, defence and medical

7th September 2020 • Read »

Digital Projectors and Video Measurement Microscopes in sharp focus at MACH

Although shadowgraphs have been available for many years they remain a popular choice for many parts with complex profiles, such as screw threads, gear teeth, nozzles, fuel injectors, and other precision components. Developed to meet modern-day needs, the Schneider digital projector range combines proven projector technology with digital image processing and analysis, including import of DXF files for rapid comparison.

Digital projector with DXF import

Traditional shadowgraphs allow the critical features of a workpiece to be projected in silhouette but the Schneider digital projector also uses an LED top light illumination system to view additional component features. This combined with a high resolution digital camera gives a noticeably sharp, distortion free image, clearly displayed on an integrated touchscreen panel PC. The built-in software has integrated overlays (eg cross hairs and concentric circles) and allows DXF files to be imported. Once the DXF is positioned over the image of the workpiece, the software ‘locks’ the DXF file over the component for fast definition of circles, lines, angles and more.

The digital projector incorporates a high precision measuring stage (with measuring range options up to 500x200mm) and various objective options for magnifications from 10x to 60x.

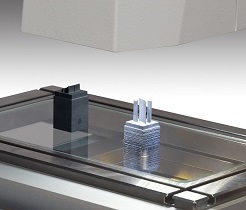

WM1 video measurement microscope with incident light

Where more rigorous measurements are required, the Schneider WM1 video measurement microscope takes camera based measurement one step further. The WM1 combines a high resolution CCD camera with top light illumination and a precision measurement stage for the best possible clarity of image. The system has precise edge detection in transmitted or incident light conditions thanks to intelligent image analysis algorithms. Configured to meet individual requirements, the CNC model can also be extended into a multi-sensor device with the addition of a tactile probe. A range of image field sizes are available or manual/motorised zoom can be selected.

The digital projector and workshop microscope are just 2 of the metrology systems in the Schneider range, which also includes shaft measurement systems, large volume profile projectors and rapid 2D measurement devices. Spectrum Metrology will be on stand H18-341 in the Inspection Zone at the MACH exhibition (NEC, 9-13 April 2018) and will be pleased to discuss your measurement requirements. Or contact us for further details.