News: Industry News

18th October 2018

More News

4D Technology event at Rolls-Royce Technology Hub, Derby University

Seminar: 3D micro-surface measurements of precision components, Wednesday 8th November 2023, 8.30am - 12.15pm

12th October 2023 • Read »

4D Technology event at Glyndwr University, 16 March 2023

4D Technology in conjunction with Quantum Design are hosting a workshop ‘Inteferometry for Metrology’ at the OpTIC Technology Centre, Glyndwr University, St Asaph on 16 March 2023.

23rd January 2023 • Read »

Alignment and Level in the Nuclear Industry

Taylor Hobson measurement products have been used for many years in the nuclear industry for checking, measuring and monitoring alignment and level. Camera systems and motorised focus accessories allow the telescope to be operated remotely from the telescope.

13th September 2022 • Read »

A fresh approach to dimensional metrology from the comfort of your desk

An easy way to view the full dimensional metrology range in one virtual showroom:

8th July 2021 • Read »

peen marking / engraving - micro features

Peen marking/engraving for parts identification is a critical element in industries such as aviation, defence and medical

7th September 2020 • Read »

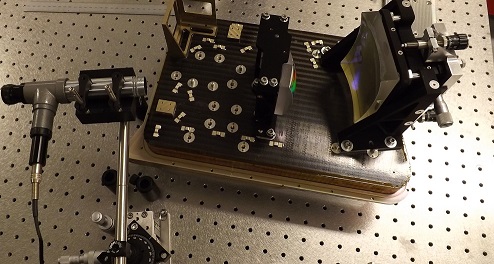

Autocollimator used to test innovative Scanner System to monitor pollution

A team from the University of Leicester’s department of Physics and Astronomy have been developing leading space technology to monitor air pollution around Leicester and Peterborough, using a specially designed camera fitted to an aircraft. Using the Taylor Hobson autocollimator, the scientists were able to align the optics in their camera to gain the sharpest possible image for accurate and repeatable results.

The University of Leicester’s space scientists successfully carried out the tests earlier this year using an aircraft equipped with a pioneering CompAQS scanner to measure air pollution, in particular nitrogen dioxide, in the environment. The instrument is part of a major initiative to improve the UKs leadership in space instrumentation for Earth Observation and the University is hoping to send the CompAQS on a space mission in the early 2020s.

The CompAQS was designed, built and tested at the University of Leicester in collaboration with Surrey Satellite Technology Ltd and DL Optics Ltd. It monitors visible light and measures how much light is lost at specific wavelengths absorbed by nitrogen dioxide. Using this information, researchers can determine how polluted areas of the landscape are, including motorway junctions, airports, carparks and urban environments. This is valuable data to allow planners to mitigate the impact of pollution on health.

TA60 autocollimator used to align optical components

It was important to align the optics in the camera in order to gain optimum accuracy and give repeatable results. To align the optical components within the scanner a Taylor Hobson autocollimator was used.

An autocollimators main use is to measure the angle of a mirror or optical component. Using the laws of reflection, when the mirror is square to the autocollimator the reading is 0,0. In its simplest form the autocollimator can be used to align optical components by putting them all in line and square. Another feature of an autocollimator is that although it is focused at infinity for angle measurement you can add an objective lens (using a thread at the end of the barrel) and focus the autocollimator to align optical components.

This principle was used to align the optics in this specialised scanner – using the autocollimator to first measure the offset in the centre of curvature between the lens and the grating, then to align the mirror.