News: Industry News

23rd April 2020

More News

4D Technology event at Rolls-Royce Technology Hub, Derby University

Seminar: 3D micro-surface measurements of precision components, Wednesday 8th November 2023, 8.30am - 12.15pm

12th October 2023 • Read »

4D Technology event at Glyndwr University, 16 March 2023

4D Technology in conjunction with Quantum Design are hosting a workshop ‘Inteferometry for Metrology’ at the OpTIC Technology Centre, Glyndwr University, St Asaph on 16 March 2023.

23rd January 2023 • Read »

Alignment and Level in the Nuclear Industry

Taylor Hobson measurement products have been used for many years in the nuclear industry for checking, measuring and monitoring alignment and level. Camera systems and motorised focus accessories allow the telescope to be operated remotely from the telescope.

13th September 2022 • Read »

A fresh approach to dimensional metrology from the comfort of your desk

An easy way to view the full dimensional metrology range in one virtual showroom:

8th July 2021 • Read »

peen marking / engraving - micro features

Peen marking/engraving for parts identification is a critical element in industries such as aviation, defence and medical

7th September 2020 • Read »

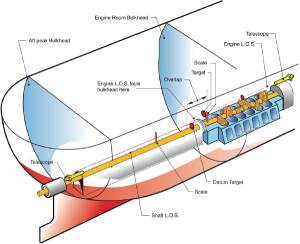

Taylor Hobson Alignment Telescopes help shipbuilding industry meet their green credentials

Shipbuilders face the challenge of reducing their environmental impact. Accurate alignment of engines, propeller shafting and stern tubes all reduce vibration and wear - which cause fuel inefficiencies - so the Taylor Hobson alignment telescope is an invaluable tool to shipbuilders and marine engineers across the globe.

Alignment of ships engine

Shipbuilders and marine engineers have used the Taylor Hobson Micro Alignment Telescope range for applications such as alignment of propulsion machinery since the late 1930s. These Alignment Telescopes (used for checking and setting straightness and alignment) are typically used to precisely align the position of the ships engine in relation to the propeller shafting and stern tube. Other tasks include alignment of the engine to the stern tube and alignment of rudder bearings. Every percentage of fuel efficiency achieved by reducing these misalignments saves around 1500 gallons of fuel – over the lifetime of a ship this can equate to millions of dollars in savings.

In recent years the capabilities of the Telescopes have been enhanced with the use of new camera technology for remote viewing when working in difficult locations and over very long distances and computerised measurements. Equally, the Micro Alignment Telescope has the advantage of being capable of running entirely without power if circumstances so dictate.

Large diesels used in marine engines are prone to twisting and deformation during periods of extended service. Before re-machining off main bearings, the alignment telescope is used to quickly and accurately assess the amount of deformation of the engine bores and determine the precise amount of metal removal. First the engine bores are measured - any misalignment can be viewed by the operator through the camera system which is attached to the Micro Alignment Telescope eyepiece. Once all the bore centres are in line and with the telescope in place, the boring machine tool is moved along the same line for machining, skimming any bores to the correct size.

The Alignment Telescope is sold around the world through Taylor Hobson’s worldwide network – the equipment is also available on hire from their technical support agent Spectrum Metrology for individual jobs during refurbishment projects.

Click here for more information on the Micro Alignment Telescope